The international maritime shipping industry is responsible for 3% of all human activity-related GHG emissions. This staggering statistic – along with growing global scrutiny – has prompted the IMO to set ambitious goals regarding the industry’s future emissions. By 2030, for example, the plan is to successfully implement a strategy that will allow the shipping industry to reduce maritime emissions by 40%. By 2050, the IMO strives to reach net-zero in terms of GHG emissions.

The key to sustainability at sea: Maritime decarbonization technology

In order to live up to its GHG maritime emission goals, the shipping industry must promote the use of advanced tools, solutions and technologies that can actively help vessels reduce energy consumption and emit less pollutants. The key to GHG emission goal attainment lies in two key areas: Reduced ship fuel consumption and effective energy utilization.

Not all shipping vessels and fleets are created equal, and therefore assisting every shipping vessel in realizing its individual decarbonization potential is a top priority. Some ships are more advanced in age than others, and implementing the same solutions used by new vessels on older sea carriers may prove challenging – especially in terms of energy-efficient hull design. That said, waiting for entire fleets to retire their old vessels and replace them with new ships is not compatible with current GHG emission plans.

Therefore, the key to advancing GHG emission goals is to promote the integration of a slew of maritime decarbonization technologies that can be implemented side by side, on both existing and new vessels, without necessitating extensive modifications or resource investments.

The following decarbonization solutions for vessel fleets have either been proven effective or show incredible potential in lowering ships’ energy and fuel emissions. Some are relatively simple to implement on a variety of carriers, while others present certain complexities.

Onboard Carbon Capture Systems (OCCS)

As their name suggests, Onboard Carbon Capture Systems are designed to capture CO₂ emissions directly from a ship’s exhaust. Instead of spreading into the air, the emissions are stored in a special unit and offloaded into an on-shore specialized facility. According to a white paper written by DNV, OCCS technology is highly inspiring, yet requires ships to accommodate numerous conditions before implementation – including on-board space allocation, system installation, and connectivity with many of the ship’s systems. OCCS is a highly advanced option for carbon emission reduction, yet it is clear that not all ships can comply with the necessary space and implementation requirements.

Wind Assisted Propulsion System (WAPS)

Wind Assisted Propulsion Systems are technologies that use wind energy to help propel the ship forward. By effectively delivering an additional source of renewable energy, WAPS reduces engine energy emissions and fuel consumption. WAPS come in a variety of designs and configurations, from soft and hard wing sails to suction wings and towing kites. The good news is that WAPS can usually be installed in retrofit, regardless of vessel age or condition. Yet their installation and implementation can be costly.

Air Lubrication Systems

These advanced systems rely on simple logic – reducing the ship’s water resistance via a constant flow of air bubbles generated at the bottom of the hull. By reducing ship-water friction, the ship needs less energy to thrust forward, and thus can save fuel and reduce its emissions. The downside is that these systems require a very specific hull design in order to be effective. In addition, several key modifications must be made to the vessel to make sure the bubbles are evenly distributed and retain a uniform shape. Therefore, these systems are not compatible with many vessels currently sailing the seas.

Waste Heat Recovery Systems (WHRS)

Waste Heat Recovery Systems are designed to capture excess heat from a ship’s engine and repurpose it for auxiliary functions. When implemented effectively, this process reduces the overall fuel required for operations. According to a study conducted by dredging solution company Royal IHC, implementing WHRS on dredger vessels can potentially lead to approximately 2%-6% in fuel savings. In some cases, as documented by heat transfer and fluid separation solution provider Alfa Laval, savings can reach as high as 14%.

Digital Twin Models

Digital twin technology allows fleet managers to create an exact virtual “twin” for specific vessels, as a basis for real-time simulations of actual scenarios in digital environments. The data twin is created by connecting vessels to advanced sensors and other data-capturing devices. Once the replica is established, the management team can use the digital twin as an accurate monitoring mechanism for energy and fuel consumption, as well as a predictive tool for expected outputs. Cutting-edge simulations can detect fallacies pertaining to unnecessary emissions, while providing insights into ways for reducing energy and fuel consumption during specific voyages.

AI-Driven Solutions: Translating data into decarbonization

Artificial intelligence is transforming the maritime shipping industry across all parameters, and is playing a key role in its decarbonization efforts.

AI-Powered route optimization is gradually becoming an industry standard. To determine the most efficient path for the ship at any given moment on its journey, AI-driven route optimization systems use computer vision technology and machine learning capabilities to analyze weather conditions, ocean currents and vessel performance. This technology can reduce fuel consumption by up to 10%, depending on voyage specifics.

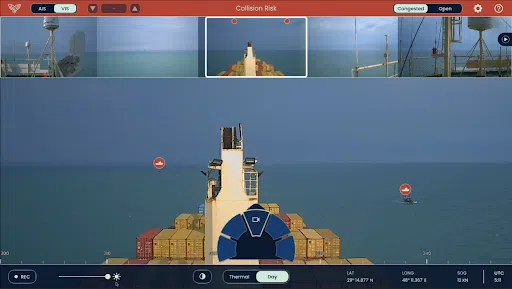

When it comes to sustainability, perhaps one of the most influential benefits of maritime AI is its enhancements of situational awareness. AI-driven situational awareness systems such as Orca AI’s SeaPod are able to detect and classify objects and patterns within a specific range, which may impact the ship and require fuel-burning maneuvering. This includes everything from other vessels and buoys to debris and large sea mammals, which SeaPod can prioritize according to projected risk. Perhaps more importantly, AI-generated data analysis leads to accurate predictions that can forecast potential hazards up ahead – giving the crew enough time to prepare for swift changes and avoid making abrupt movements that use up more fuel and energy.

Furthermore, AI improves ships’ weather predictability capabilities. Running into bad weather puts extra strain on the ship’s engine and increases fuel consumption due to sudden accelerations and maneuvering. Advanced weather forecasting tools are crucial for ships who want to avoid unexpected storms, fog and high winds. Apart from the obvious safety benefits, ships using real-time weather predictions can save up to 2%-4% in energy consumption by optimizing their route to stay clear of adverse conditions.

In addition to relying on predictions delivered from reliable large-scale sources such as the ECMWF’s Integrated Forecasting System (IFS) and the US National Weather Service’s Global Forecast System (GFS), ships equipped with AI-powered bridge lookouts can detect and predict small-scale weather events such as rain or fog that are often missed – and yet can have serious implications on vessel energy consumption.

Key tips for maritime decarbonization technologies

Every technology reviewed above is designed to create significant impact. While some require major resources for effective implementation, others can be installed and deployed on existing and timeworn ships with minimal or no structural changes. As decarbonization in the marine industry continues to gain traction, here are some things worth remembering:

Solutions should work together

Implementing different solutions that can work together in unison, one alongside the other, to provide a cumulative reduction in fuel and energy consumption, is a huge advantage. While not every solution may be a perfect fit for every ship, fleets should attempt to tailor the ideal solution portfolio for every one of their vessels, based on vessel type, age, voyage intensity and integration capabilities. Deciphering the optimal combination of solutions for specific vessels may require a thorough professional assessment.

Embracing data

Data collection and analysis are paving new roads for more effective and more sustainable shipping. Whether AI-driven or not, cutting-edge technologies are measuring and assessing data to tell us more about our ships and their voyages than ever before. As a result, the shipping industry is better equipped to reach a variety of key parameters. For example, data collected by Orca AI’s solutions across years of global operations and thousands of nautical miles has helped identify correlations between ships’ acceleration patterns and fuel consumption, and has led to the insight that fewer accelerations – due in part to AI-generated predictions – lead to fuel savings. The bottom line is this: smarter ships, which are able to collect and analyze data, can lower their carbon footprint with greater simplicity.

Overcoming barriers with ease

Integrating new solutions across entire fleets – or even on select ships, for that matter – requires a commitment to change. This change can feel daunting to decision-makers for a number of reasons. A commitment to new solutions not only requires appropriate budgeting and resource allocation, but also staff training and a certain abandonment of old habits for unfamiliar practices. Yet it is important to remember that many new solutions – including Orca AI’s SeaPod and FleetView systems – have been built not only to deliver optimal results, but also to facilitate seamless integration, with minimal crew training, smooth installation and easier adoption.